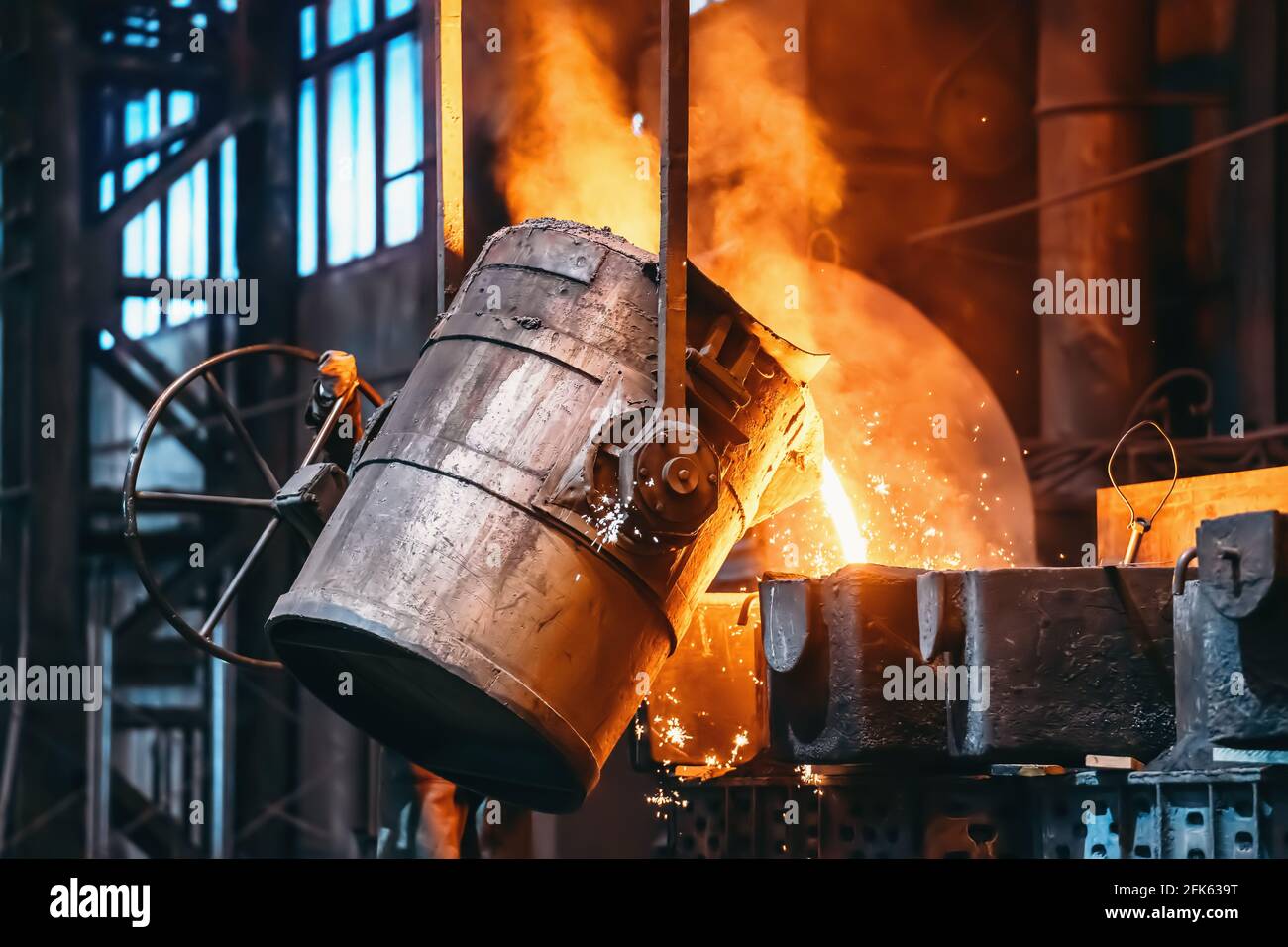

Closer Look into How a Metal Foundry Operates

Wiki Article

Recognizing Metal Casting Procedures: Developments and Patterns in the Foundry Market

The foundry market is experiencing substantial changes driven by technical developments. Technologies such as 3D printing and man-made knowledge are reshaping metal casting processes, improving effectiveness and precision. Sustainable techniques are getting grip, emphasizing the relevance of environmental duty. Furthermore, the intro of sophisticated products and automation is improving general casting high quality. These advancements suggest a pivotal change in the sector, questioning about future directions and ramifications for manufacturers.Improvements in 3D Printing for Metal Casting

Recent improvements in 3D printing modern technology have substantially changed the landscape of steel casting. The assimilation of additive production techniques has actually allowed the fast manufacturing of complex patterns and mold and mildews that were formerly hard or difficult to achieve with conventional techniques. By utilizing materials such as sand and metal powders, producers can produce detailed geometries that boost style flexibility and reduce material waste. This development not just expedites the prototyping procedure yet likewise enables for the personalization of parts customized to details applications.

3D printing helps with much shorter lead times, which is essential in industries requiring fast turnaround for parts. The modern technology additionally sustains the manufacturing of light-weight frameworks, consequently boosting power performance in output. As a result, the foundry industry is experiencing a change towards more lasting techniques, driven by the performance and precision provided by these modern-day 3D printing techniques in metal casting procedures.

The Role of Expert System in Precision Production

As industries significantly embrace advanced manufacturing innovations, expert system (AI) is playing a crucial function in boosting precision manufacturing procedures. AI algorithms analyze large datasets to optimize and recognize patterns manufacturing parameters, resulting in improved precision and efficiency. In steel casting, AI help in anticipating upkeep, minimizing downtime by forecasting devices failings prior to they occur.Furthermore, AI-driven simulations make it possible for makers to model the casting process, refining styles and minimizing defects. Artificial intelligence techniques enhance quality assurance by spotting anomalies in real-time, therefore making certain that just items meeting rigid specifications continue through the assembly line.

Lasting Practices in the Foundry Market

Sustainability has actually become a vital focus in the foundry sector, triggering producers to take on techniques that minimize ecological influence while preserving performance - Metal Foundry. One famous technique includes the recycling of products, particularly metals, which significantly reduces waste and energy intake. Foundries are progressively implementing closed-loop systems, permitting the reuse of sand and various other casting products, thereby reducing the demand for virgin resourcesOn top of that, energy-efficient modern technologies, such as electric heating systems, are getting grip, as they reduced greenhouse gas discharges contrasted to typical methods. Lots of foundries are discovering the use of environmentally friendly coatings and biodegradable binders to lower hazardous byproducts. Employee training on sustainable practices has likewise come to be necessary, fostering a culture of ecological duty within companies. Generally, these lasting techniques not only add to ecological preservation however likewise boost the long-term viability of the foundry sector in a progressively eco-conscious market.

Technologies in Products for Improved Casting Quality

With the constant development of the foundry sector, developments in products have actually ended up being important for enhancing casting high quality. Advanced alloys and composite materials are significantly being used to improve mechanical buildings and lower issues in castings. These materials frequently use premium strength-to-weight proportions and improved resistance to corrosion and wear, resolving the needs of modern-day applications.Furthermore, the consolidation of nanomaterials is obtaining grip, enabling finer microstructures that bring about improved surface finishes and dimensional accuracy. Metal Casting. 3D printing innovations also contribute in creating complex geometries with marginal waste, allowing the use of specialized materials that were formerly testing to cast

Moreover, the growth of eco-friendly binders and additives contributes to sustainable techniques while preserving premium results. Jointly, these technologies not only enhance the efficiency of actors products but additionally line up with the industry's shift in the direction of sustainability and effectiveness.

Automation and Robotics in Metal Casting Processes

Automation and robotics are revolutionizing steel casting procedures by enhancing and streamlining procedures precision. In modern factories, robotic systems are utilized for tasks such as mold and mildew handling, pouring, and ending up, considerably minimizing human treatment. This not only reduces the threat of mishaps however likewise guarantees consistent high quality in production.Automation innovations, such as computer numerical control (CNC) makers, help with detailed layouts and complicated geometries that were formerly testing to achieve. Real-time data analytics allow manufacturers to maximize and monitor processes efficiency continually.

Check The assimilation of automation causes enhanced productivity and performance, enabling factories to satisfy expanding market needs while reducing lead times. As the sector embraces these innovations, the workforce is also advancing, needing new skills to run and keep innovative machinery. On the whole, the fostering of automation and robotics is a pivotal pattern shaping the future of steel casting processes.

Regularly Asked Inquiries

What Is the Background of Metal Casting Strategies?

Metal casting methods go back to old civilizations, with proof of bronze casting in Mesopotamia around get more info 3000 BCE. Over centuries, approaches advanced substantially, integrating advancements in materials and modern technology, forming modern-day industrial techniques.Just How Does Metal Casting Effect the Environment?

Metal casting considerably affects the atmosphere via power usage, exhausts, and waste generation. Nevertheless, developments in sustainable techniques and modern technologies aim to alleviate these results, advertising even more eco-friendly approaches within the market.What Precaution Are Essential in Shops?

What Prevail Flaws in Metal Casting Products?

Typical defects in metal casting products include porosity, shrinkage, misruns, cold shuts, and surface blemishes. These problems emerge from elements such as inappropriate temperature level control, inadequate mold style, and contamination throughout the casting process.Just How Do Foundries Ensure High Quality Control in Casting Processes?

Factories implement strenuous quality assurance steps through routine inspections, standardized testing, process tracking, and adherence to market standards. These practices assist identify issues early, ensuring the honesty and dependability of the final casting items.Technologies such as 3D printing and synthetic knowledge are reshaping metal casting procedures, enhancing performance and precision. Current advancements in 3D printing technology have actually significantly transformed the landscape of metal casting. Automation and robotics are reinventing metal casting procedures by improving procedures and boosting precision. Metal casting methods day back to old civilizations, with evidence of bronze casting in Mesopotamia around 3000 BCE. Typical issues in metal casting items include porosity, contraction, misruns, cold shuts, and surface area imperfections.

Report this wiki page